FAQs

STORE FAQ'S

All of our non-Clearance wheels and tires come with a manufacturers warranty. Clearance items do not come with a warranty as many times the wheel is being discontinued, and will on longer be available.

Most wheels come with 1 year warranty on the finish, and lifetime structural warranty against any manufacturers defects. Tire warranties depend on the manufacturer and model of the tire. Please see the manufacturers website for complete warranty information.

Some manufacturers deal directly with the consumer in handling warranties, but generally Eurowheelsusa will facilitate warranty exchanges. Please note that defective products will only be replaced with the exact same product, and cannot be substituted for a different item. Eurowheelsusa is not responsible for any costs associated with the exchange of a warranty item such as shipping back and forth, labor charges, time, etc. Any costs associated with the exchange will be the responsibility of the customer. The role of Eurowheelsusa is to only facilitate exchanges, as Eurowheelsusa does not manufacture any wheels or tires.WHEEL TECH FAQ'S

CUSTOM WHEELS OFFSET GUIDE | THE ART AND SCIENCE OF THE PERFECT FITMENT

WHAT IS A WHEEL OFFSET

Offset, or what the industry refers to as "ET" is the distance between the center of the rim, and the mounting surface of the wheel that contacts the vehicle hub. A simple way to understand offset, is the lower the offset, the more the wheel will stick out, likewise, the higher the offset, the more the wheel will tuck in. For example, and Honda Civic generally uses around a +40mm offset. So if you put a +15mm offset wheel on the car, the wheel is likely to stick out about 1 inch. If you've ever noticed a lifted truck or a low rider with wheels sticking out, its because the offset of the rim is very low and in many cases so low that they are negative offsets.

Its important to note that offset is normally measured in millimeters and backspacing is normally measured in inches.

WHAT IS THE DIFFERENCE BETWEEN WHEEL OFFSET AND BACKSPACING

Measuring backspacing is another way to determine how far in or out a wheel will sit. Backspace and offset both measure the wheel positioning, but in different ways. You can convert backspacing to offset by using a fairly simple calculation.

HOW TO MEASURE THE OFFSET OR BACKSPACING OF A RIM

To measure backspacing or offset, you'll lay the wheel face down, and lay a straight edge across the back of the wheel. Using the straight edge as an indicator for the back of the wheel, you will measure the "Backspacing" which is distance from the back of the wheel to the back pad (the part of the wheel that mounts up to the vehicle hub).

To measure offset, you'll have another step. Start by measuring the entire rim width. Be sure not to use the published width of the wheel found stamped on the wheel. The actual width of the wheel is normally 1 inch more than the published width since the industry publishes rim width by measuring the distance between bead seats, which is where the tire meets the rim. To determine offset, use the following calculation:

offset = 25.4 x (backspacing -.5 x full rim width)

So for instance, if you have a wheel that has a size of 20x9, then the actual width is most likely 10 inches wide. If the backspacing is 7 inches, then the calculation is as follows

offset = 25.4 x (7 - .5 x 10)

offset = 50.8mm

Its important to note that backspacing is normally measured in inches

HOW DOES RIM OFFSET AND RIM WIDTH AFFECT FITMENT

Finding the perfect wheel and tire fitment requires a careful calculation of wheel width, wheel offset and tire size. Eurowheelsusa has used 60 years worth of combined knowledge base to determine the ideal fitment for your vehicle. The positioning of the face, or outside of wheels with varying widths can be accomplished by selecting different offsets. For instance the positioning of the face of the wheel of a 20x10 +25mm offset is the same as a 20x10.5 with a +31mm offset. This is because the extra width of the 20x10.5 inch wheel is compensated by the higher offset bringing the wheel in an extra 1/4 inch putting the face of the wheel in the same position as the 20x10. These adjustments of offset to accomplish the perfect look on your car need to be carefully considered when trying to put wider wheels on because other factors need to be considered such as tire size and suspension parts, and wheel well clearance.

CUSTOM WHEELS OFFSET GUIDE | THE ART AND SCIENCE OF THE PERFECT FITMENT

WHAT IS A WHEEL OFFSET

Offset, or what the industry refers to as "ET" is the distance between the center of the rim, and the mounting surface of the wheel that contacts the vehicle hub. A simple way to understand offset, is the lower the offset, the more the wheel will stick out, likewise, the higher the offset, the more the wheel will tuck in. For example, and Honda Civic generally uses around a +40mm offset. So if you put a +15mm offset wheel on the car, the wheel is likely to stick out about 1 inch. If you've ever noticed a lifted truck or a low rider with wheels sticking out, its because the offset of the rim is very low and in many cases so low that they are negative offsets.

Its important to note that offset is normally measured in millimeters and backspacing is normally measured in inches.

WHAT IS THE DIFFERENCE BETWEEN WHEEL OFFSET AND BACKSPACING

Measuring backspacing is another way to determine how far in or out a wheel will sit. Backspace and offset both measure the wheel positioning, but in different ways. You can convert backspacing to offset by using a fairly simple calculation.

HOW TO MEASURE THE OFFSET OR BACKSPACING OF A RIM

To measure backspacing or offset, you'll lay the wheel face down, and lay a straight edge across the back of the wheel. Using the straight edge as an indicator for the back of the wheel, you will measure the "Backspacing" which is distance from the back of the wheel to the back pad (the part of the wheel that mounts up to the vehicle hub).

To measure offset, you'll have another step. Start by measuring the entire rim width. Be sure not to use the published width of the wheel found stamped on the wheel. The actual width of the wheel is normally 1 inch more than the published width since the industry publishes rim width by measuring the distance between bead seats, which is where the tire meets the rim. To determine offset, use the following calculation:

offset = 25.4 x (backspacing -.5 x full rim width)

So for instance, if you have a wheel that has a size of 20x9, then the actual width is most likely 10 inches wide. If the backspacing is 7 inches, then the calculation is as follows

offset = 25.4 x (7 - .5 x 10)

offset = 50.8mm

Its important to note that backspacing is normally measured in inches

HOW DOES RIM OFFSET AND RIM WIDTH AFFECT FITMENT

Finding the perfect wheel and tire fitment requires a careful calculation of wheel width, wheel offset and tire size. Eurowheelsusa has used 60 years worth of combined knowledge base to determine the ideal fitment for your vehicle. The positioning of the face, or outside of wheels with varying widths can be accomplished by selecting different offsets. For instance the positioning of the face of the wheel of a 20x10 +25mm offset is the same as a 20x10.5 with a +31mm offset. This is because the extra width of the 20x10.5 inch wheel is compensated by the higher offset bringing the wheel in an extra 1/4 inch putting the face of the wheel in the same position as the 20x10. These adjustments of offset to accomplish the perfect look on your car need to be carefully considered when trying to put wider wheels on because other factors need to be considered such as tire size and suspension parts, and wheel well clearance.

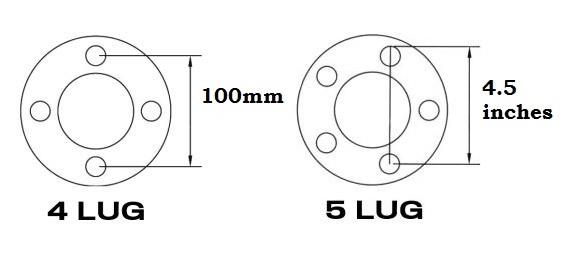

BOLT PATTERN, BOLT CIRCLE DIAMETER: (SEE DIAGRAM A)

CENTERBORE: (SEE DIAGRAM A)

STAGGERED WHEELS AND TIRE PACKAGES

HUGE SELECTION OF STAGGERED WHEELS AND RIM AND TIRE PACKAGES

Eurowheelusa.com is your wheel fitment specialist and has been specializing specifically in custom fitments and staggered wheel and tire fitments for over 15 years. Start by entering your vehicle in the search box above and find the largest selection of staggered wheels in sizes ranging from 15" to 24". We've made is simple to find every possible fitment for your vehicle so give it a try, and if you have any questions, our wheel fitment specialists are available to answer any questions you may have.

WHAT ARE STAGGERED WHEELS?

When you see staggered wheels, that means the wheels on the back of the vehicle are a different size than the front. Most common staggered rim fitments will be wider wheels in the rear of the vehicle such as 19x8.5 front wheels and 19x10 rear wheels. On some vehicles such as the Acura NSX, Chevrolet Corvette, and others you will find wheels in the rear that are both wider, and usually 1 inch larger in diameter. Typically staggered fitment wheels are found on rear wheel drive vehicles such as Infiniti G35, Nissan 350Z, many BMW applications, Mercedes Applications, Audi, VW, Ford, Porsche and many more.

IS A STAGGERED APPLICATION OK TO USE ON AWD?

It depends on the manufacturer of the vehicle, but generally staggered wheels are not recommended for AWD (All Wheel Drive) vehicles. Most AWD vehicles have been engineered to perform their best with the same size wheel front and back, so you may suffer a decrease in performance and handling of the vehicle. However in recent years staggered wheels have become more and more available on many high performance sports cars such as the Nissan GTR, Audi R8, and many others. With that said, even if your car did not come with staggered wheels from the factory, most vehicle's computer systems can adjust for the small variance in rolling diameter between the front and wheel tires, and usually do not cause any harm to the vehicle. Some AWD vehicles such as the E Chassis BMW, Infiniti, and Tesla are particularly sensitive to putting different size tires on the front compared to the rear.

CAN I PUT STAGGERED WHEELS ON A FRONT WHEEL DRIVE CAR?

In some cases FWD (Front Wheel Drive) cars have enough room in the rear to fit a wider wheel such as the Acura TL but generally speaking you will have to make fender modifications in the rear to fit a wider wheel and tire. If you want the staggered look with a larger lip in the rear, many wheel companies have introduced a simulated staggered application. What this means is the front and rear wheels are the same diameter and width, but the rear wheels have a bigger lip. They are able to accomplish this by setting the spokes on the rear wheels further in the wheel to give it a bigger lip. Sometimes you can get as much as a 4 inch lip in the rear.

TAKE A LOOK AT SOME OF OUR MOST POPULAR STAGGERED WHEEL BRANDS

CONCAVE WHEELS AND TIRE PACKAGES

The phenomenon known as concave wheels has changed the wheel game forever and has become the newest trend in aftermarket wheels worldwide. Replacing the classic look of the typical lips on wheels, concave wheels gives a car the ultimate depth in looks while looking larger than the traditional deep lip wheel because of the spokes extension to the outer edge of the rim.

WE'VE GOT THE LARGEST SELECTION OF CONCAVE WHEELS ON THE MARKET

Eurowheelsusa has been on the forefront of concave wheels, and we've established ourselves as experts in finding the deepest concave wheels on the market for your car, truck, or SUV. Search thousands of concave wheels on our website by simply using our easy to use search feature above. Just enter your vehicle, and see the 100's if not 1000's of concave wheels that will set off your ride perfectly.

WHAT ARE CONCAVE WHEELS?

Concave Technology is the idea of having the spoke start at the outer rim of the wheel, and drop deep towards the center of the wheel creating an extremely aggressive stance. Rather than exaggerating a bigger lip for the back wheel, and a smaller lip for the front. Concave wheels emphasize the concavity of the rear wheel to differentiate from the front wheel.

CAN I PUT STAGGERED CONCAVE WHEELS ON MY CAR?

The answer is, YES!!! Many of the Concave manufacturers build many applications to fit all sorts of vehicles. Historically staggered wheels were reserved for Rear-Wheel Drive Vehicles. But since there is a high demand for staggered wheels for Front-Wheel Drive Applications, manufacturers have answered the calling.

WHY ARE SOME WHEELS MORE CONCAVE THAN OTHERS?

The amount of concave depends on several factors including wheel width, wheel brake clearance, wheel offset, and just the way the wheel was engineered. We get a lot of calls from customers saying that they want a really concave wheel for their car, but the widest their vehicle can use is an 8.5 inch wheel. With a wheel that narrow it is very difficult to accomplish much concave. We also have to take into consideration brake clearance. The more concave a wheel is, the less brake clearance it will have. The third factor is the offset. If your vehicle requires a fairly high offset wheel, it will cause limitations on how much concave the wheel can have. So although everyone wants the most concave wheel possible, there are many factors to take into consideration.

WILL A LOWER OFFSET WHEEL BE MORE CONCAVE?

We get this question a daily basis, and the answer is... Maybe! To start, lets explain offset.

In very basic terms, offset determines how far in or out a wheel will sit on your vehicle. The lower the offset, the more it will push the wheel out. The higher the offset, the more the wheel will sit in. Every car has a range of offsets that will work on it. There is no perfect offset, since the perfect position of a wheel can be subjective. Customers that want an aggressive stance will opt for a lower offset wheel causing it to be more flush with the fender and in some cases, sticking out slightly. This is a very popular look for the rear wheel on muscle cars. More conservitive customers may want the wheel to sit in the fender more to avoid having the tire kick up rocks and dirt on the side of the car.

In more technical terms, the offset is the measurement of distance from the center of the wheel, to the back pad of the wheel (part of the wheel that mounts up to the car). So on a lower offset wheel the backpad of the wheel will be closer to the center of the wheel, causing the wheel to push out more. On a higher offset wheel, the backpad will be closer to the front (or face) of the wheel creating a larger measurement between the center of the wheel, and the backpad.

So why do people ask if a lower offset wheel will be more concave? That is because there is a large misonception in the industry that a lower offset wheel means the backpad will be closer to the center of the wheel, so that would mean that you get a really nice deep concave drop because the backpad is set in so far. This may be true for fully custom built forged wheels because they are made to order, and are tailor made to the specific vehicle maximizing design elements to provide the most aggressive stance. The idea of a fully custom wheel is great, however the reality is anything fully custom is going to have a very high cost associated to it.. In most cases the price range of fully custom wheels starts around $1000 per wheel and quickly goes up from there.

The majority of wheels on the market are cast wheels which come out of molds. So when a manufacturer offers a wheel in lets say 20x10 and offers offsets of +15mm, +20mm, +40mm, +50mm, the amount of concave is the same because the wheel comes out of the same mold no matter what the offset is. The only difference between a 20x10 +15mm offset, and a 20x10 +40mm offset is the backpad. The backpad on the +15mm offset will be 25mm thicker than the backpad of the +40mm offset. The face (or front) of the wheel does not look any different between offsets. In most cases, the only way to get a more concave wheel is to go with a wider wheel because of the way the manufacturer engineers the wheel. Generally speaking the narrow wheels are meant for front wheels, and cannot have too mach concave because of width restrictions, and because they have to account for the front brake calipers which can cause clearance issues. The wider rear wheels will usually have more concave because they do not have to worry as much about smaller rear brake calipers.

There are some manufacturers of concave wheels that will make a single size wheel such as a 20x10 with 2 different profile molds. One mold will have less concave for the higher offset applications, and the other may have a deeper concave for the lower offset applications. This is rare because the cost of making molds and minimum production numbers can be cost prohibitive, however there are some manufacturers such as MRR, Forgestar, Concept one, and a few others that have not let cost stop them from providing the deepest concave wheels possible for their customers.

TAKE A LOOK AT SOME OF OUR MOST POPULAR CONCAVE WHEEL BRANDS

CHROME RIMS FOR CARS, TRUCKS, AND SUV'S

If your looking for the largest selection of custom chrome wheels for your truck, SUV, or car, you've come to the right place. Eurowheelusa has put together the most comprehensive list of chrome plated rims of any website, so we're confident that you'll find exactly what your looking for here.

SHOULD I BUY CHROME RIMS?

If your looking to give your vehicle that extra classy look, then chrome is hands down the way to do it.. Chrome isn't necessarily going to make your wheels stand out more than any other color, but it sure will make your car, truck, or suv stand out. It has a way of subtly adding class and luxury to your vehicle that no other color wheel can accomplish.

ARE CHROME RIMS SAFE TO USE IN SNOW?

The salt that is used on the roads during snow has a corrosive property that will damage chrome plating on wheels. We would suggest you use your factory wheels during those wintery season where salt will be used on the road. If you absolutely don't want to compromise the luxury look of your ride during those times, be sure to rinse off your wheels very well anytime they may have come in contact with the salt in order to prevent any damage to your aftermarket chrome wheels. Please be aware that damaged to chrome wheels caused by salt is fairly easy to determine, and most wheel manufacturers will not warranty salt damage to chrome wheels.

WHAT IS PVD CHROME?

PVD (Physical Vapor Deposition) chrome provides a similar look to chrome plating using a different application process more similar to powdercoating and more environmentally friendly. PVD is also more light weight and if done right, more durable than chrome in climates that encounter snow, or salt in the air. PVD is a great alternative to chrome, but under close comparison, still does not quite provide the same brilliance as traditional chrome

WHY ARE CHROME WHEELS SO HARD TO FIND?

The process of chrome plating a wheel is considered to be highly toxic, and as a result the EPA and its international counterparts have established harsh regulations limiting the ability to produce chrome wheels as easily as before. As a result, many factories are limited on how many wheels they can chrome plate.

TAKE A LOOK AT SOME OF OUR MOST POPULAR CHROME WHEEL BRANDS

One question we do get a lot of the time is what’s the difference between a cast wheel, a flow formed wheel, and a fully forged wheel. And the short answer is the manufacturing processes. But how those processes matter to the end-user, that’s what we’re going to talk about in this blog.

Starting with the first process of manufacturing; CAST WHEELS

Cast wheels are the first of the three. These are the most affordable of the processes of manufacturing. Nowadays most wheel manufacturers will use a low-pressure cast manufacturing process which means molten aluminum is injected into a pressurized cast from the bottom up. This helps reduce the likelihood of air bubbles in the aluminum after the mold cools down.

Between CAST and FULLY FORGED is a sort of hybrid of the two. This one is called FLOW-FORMED

Flow Formed wheels are sometimes also called Flow Forged, Spun Forged, or Rotary Forged (there are a few different names for this process). These wheels start as a cast wheel that’s placed into a machine that spins it quickly, while steel rollers apply pressure to stretch the barrel downward to its final size and specifications. Different manufacturers tweak this process to their own unique manufacturing standards which is why this particular process gets branded differently. Because the aluminum in the barrel is physically being both compressed and stretched at the same time, this increases the strength properties of the barrel making it very close to a fully forged wheel. Most performance-oriented enthusiasts who can’t be at the track often enough to justify a fully forged wheel will purchase a Flow Formed style of manufactured wheel. Companies like ESR, MRR, Vossen, Ferrada, Avant-Garde, Rohana, Stance, Vertini, Project 6GR, and more all offer these kinds of manufactured wheels.

One thing to remember is that different manufacturers will add their own unique twist to this process that does benefit the end result.

Finally the last of the three processes is FULLY FORGED

Fully Forged wheels are the most expensive of the three different manufacturing processes. While the other two can be ordered by the container load and stored in warehouses until enthusiasts make their purchase. Fully Forged wheels are completely tailored to the enthusiast’s requests. Like nice fitted Italian suits or diamond jewelry. But these aren’t just for looks. Fully Forged wheels offer the highest levels of strength characteristics and the lightest weights of any wheel. As for the manufacturing process itself, it is very involved and advanced. A solid aluminum forging gets heated to extreme heat levels which allow pressurized machines to shape the entire wheel. Then the wheel goes into the final machining process where special programming gets employed to create the design that gets drilled into the wheel itself to create the final product. For enthusiasts that spend a lot of time at the track, this is typically the choice they go with of wheel because of how much stronger fully forged wheels are.

Whether you choose to go with Cast, Flow Formed, or Fully Forged, there’s definitely something out there available for every taste and every purpose. To be clear, just because Fully Forged wheels are the strongest, does not mean Casts wheels are weak. Cast wheels will definitely do the job especially if all you want to do is just look good going from point A to point B.

HOW TO MEASURE YOUR WHEELS | WHEEL SIZE & WHEEL WIDTH

One of the most common questions in the automotive industry is "How do I correctly measure my wheel?". This is usually a question asked when someone is planing on upgrading wheels. Although there is many measurements that go into measuring a wheel, we will touch on the most important ones here.

HOW TO MEASURE WHEEL SIZES

If you are unsure the overall size of your wheels, there are a few things to consider when attempting to measure the dimensions. You will want to find the following:

- Diameter

- Width

- Offset

- Backspacing

- Bolt Patterns

WHEEL DIAMETER

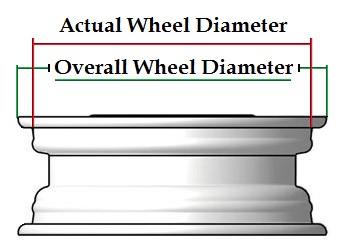

With the Wheel Diameter, keep in mind that there are two measurements to consider: Overall Wheel Diameter and Actual Wheel Diameter.

When measuring for the Overall diameter, you will want to measure from the outside lip to outside lip of the wheel (Shown by the Green Line in the photo below).

When measuring for the Actual Diameter, you will want to measure from the inside of the Barrel of the wheel (Shown by the Red Line in the above photo). Example: A wheel with an actual Diameter of 18” will have an overall diameter of around 19.5”.

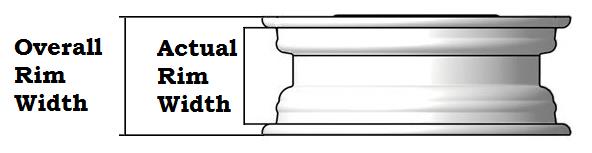

WHEEL WIDTH

Measuring the Wheel width is similar to measuring the Diameter. You will want to measure from the Barrel Section and not to overall outside width (See Picture Below).

WHEEL OFFSET

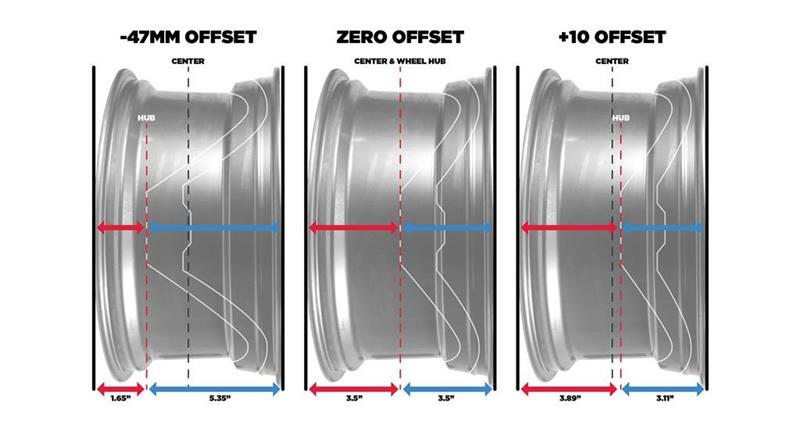

The offset of a wheel is the distance from the hub mounting surface to the center line of the wheel. This is an important measurement to keep an eye on when choosing your next set of Mustang wheels. The wheel offset is measured in millimeters and results in three different types of offsets.

The Three Types of Offset

- Positive Offset: The hub mounting surface is toward the face of the wheel.

- Negative Offset: The hub mounting surface is toward the back of the wheel.

- Zero Offset: The hub mounting surface is even with the centerline of the wheel.

WHEEL BACKSPACING

The backspacing is the distance from where the hub section of the wheel contacts the hub surface of the car to the back lip of the wheel (See picture below). Backspacing is always measured in inches and is closely related to the offset so that means when you change one it immediately affects the other.

This is extremely important because it determines the clearance of the wheel in the wheel well. Also, it affects how much the wheel will stick out past the fender. You can measure a wheel’s backspacing by running a straight edge across the rim bead (without a tire) and dropping another straight edge or Tape measure/ruler down to the wheel face, measuring that distance. (See picture below)

BOLT PATTERN

The bolt pattern consists of two numbers and looks like this: 5×4.50. The first number in this example(5) indicates how many bolt holes or studs are on the vehicle while the other number (4.50) describes the diameter of the circle formed by those 5 holes or studs. They are listed in either inches or millimeter units (4.50 is inches). Another example: a bolt pattern of 4×100 indicates a pattern with 4 lugs on a circle with a diameter of 100mm.

Using these tools, you will be able to find the overall dimensions of the wheels you have! Many wheel manufacturers will also have the Diameter and Width Cast in the back of the wheel (example: 17x9) to make it easy to know the main size.

PVD (Physical Vapor Deposition) Chrome was originally designed for the aerospace industry and has since become a highly popular finish in the automotive industry. Unlike traditional chrome platting, that pits and peel with normal wear and tear. PVD Chrome is a highly durable process that exceeds the life of chrome platting.

PVD Chrome plating is a 100% environmentally green process unlike tradition chrome plating. PVD wheels are 80% lighter than chrome plated wheels which leads to increased fuel economy.POWDERCOAT VS. PAINT | PROS & CONS

Powder coating is increasing in popularity in comparison with wet painting due to its durability. Metal parts can be finished with either powder coating or wet paint. While they serve a similar function, each coating type has a unique set of advantages and disadvantages. Both coatings contain resins, additives, and pigments. The major distinction is solvent: wet paint contains solvent, but powder coating doesn’t. The solvent in wet paint keeps all the other components in suspended liquid form. In contrast, powder coating is applied as a dry powder. All the other differences between powder coating and wet paint—application method, color matching, texture, and even operator training requirements stem from that basic difference in chemical composition.

POWDER COATING VS PAINT

New technological advancements and decreasing costs are driving up the popularity of powder coating, especially in industrial applications. While there will always be a role for liquid paint, you can expect to see more powder coating on the market in the future.

APPLICATION PROCESSES

Despite being applied in different states (liquid versus solid), the industrial application methods for powder coating and liquid paint are surprisingly similar. Pretreatment is identical in both processes. Before any coating can be applied, the surface needs a thorough cleaning. Any oil, dirt, moisture, or other contamination will interfere with surface adhesion. After cleaning, the processes diverge slightly.

POWDER COATING

The application of powder coating relies on negatively charged dry powder being attracted to grounded metal parts. For the powder coating process, dry powder is shot through an electrostatic gun on to the metal exterior. The gun gives the powder a negative charge, and the negatively charged powder is attracted to the grounded part. The attraction results in fast, even application. Once the coating reaches the desired thickness, the coated piece is placed in a curing oven, where the heated powder gels. Curing creates thermal bonds between powder particles, resulting in a smooth, hard finish.

WET PAINT

Liquid paint is dispensed in a fine spray. It is also electrostatically charged, but to much less effect. While powder coating forms even coats with almost effortless ease, liquid paint needs to be applied by highly trained experts to avoid drips or sags. Some liquid paints are air dried, while others are placed in a curing oven. It is normal for both powder coating and liquid paint to include a primer and a color coat, however, liquid paint may also include multiple color coats and a clear top coat.

TEXTURES

In some applications, the appearance of the finished paint job is nearly as important as performance. Some textures can be attained equally well by powder coating or wet paint, but others are easier to achieve with a particular medium. Textured finishes are much easier to attain with powder coats. Thinner powder coats are naturally more textured, while thicker layers are smoother. It is technically possible to attain a high-gloss finish with powder coating, but it is much easier with liquid paint.

COLOR MATCHING

Powder coating has many strengths, but liquid paint is the unequivocal winner when it comes to color matching.

Custom colors of liquid paint can be mixed on-site, and with a high degree of precision, by almost any paint supplier. A blue and red pigment can be mixed to produce purple paint.

In contrast, custom powder coat colors require a special production run. The color of powder coatings is determined by the plastics ground down to form it. There is no solvent in powder coating, so an attempt to blend blue and red powder will just create a blue and red speckle pattern. Because it is hard to color match, powder coating is usually produced in large batches of standard colors. Custom orders are possible, but more time consuming and expensive than color matching with wet paint.

PERFORMANCE

A finish is meant to protect metal surfaces from corrosion and other environmental damage. If the finish is damaged by scratching or chipping, it ceases to function as an effective barrier.

Powder coating provides better performance than wet paint—it is more resistant to chipping, scratching, and other wear because of the thermal bonding it undergoes during curing, and because it can be applied in much thicker layers. This performance is especially important for outdoor products. In addition to its physical toughness, powder coating provides superior color retention. Long term exposure to moisture, sunlight, and heat breaks down the resins found in both paint and powder coating. This process, known as chalking, causes resin and pigment particles to lose adhesion. Affected particles form a chalk-like layer on the coating surface.

The early stages of chalking merely give the coating a faded appearance, but severe chalking will eventually erode the coating enough to compromise surface protection. The rate of chalking depends on the resiliency of the resin. Polyester based powder coatings are frequently used as top coats due to their exceptional chalk resistance.

HEALTH & SAFETY

Although not extensive as liquid paint, powder coating presents a wide selection of colors to choose from.Powder coating isn’t just more durable than liquid paint—it is also safer to store and apply.

Liquid paint is hazardous for several reasons. First of all, it’s flammable. Careless storage can easily lead to a dangerous chemical fire. Wet paint is also a health hazard to the operators that work with it.

Wet paint emits volatile organic compounds (VOCs). Long term exposure to VOCs, especially in enclosed spaces, causes respiratory irritation and compounding health problems. VOCs are also a major source of industrial pollution.

Because powder coatings don’t contain any fluids to evaporate, they don’t emit any VOCs, and are completely free of the associate health and safety risks.

COST

Powder coating is usually cheaper than wet paint in the long run, but the upfront costs tend to be higher. Wet paint technology has been around a lot longer (powder coating was developed in the 1950s), so the equipment and materials are more widely available. The savings with powder coating are mostly indirect, but they add up fast.

First, powder coatings have a much better utilization rate. Unlike liquid paint, powder can be collected and reused. Approximately 70% of paint is lost to overspray during application, while material loss of powder coating can be kept under 5%.

Cost is also heavily effected by safety and environmental regulation. Because it is more hazardous, wet paint requires more investment in mitigation measures and insurance premiums. Powder coating facilities can keep these costs to a minimum.

WHAT IS TPMS?

The tire pressure monitoring system (TPMS) in your vehicle is to warn you that at least one or more of your tires are under-inflated. Under-inflated tires can cause unsafe driving conditions. The TPMS low tire pressure indicator is a yellow symbol in the shape of a tire cross-section with an exclamation point.

Before this indicator light, knowing if your air pressure had reached unsafe levels meant getting out, and using a tire gauge on each individual tire. With some exceptions, this was the only pressure-checking tool known to the public. In response to a surge in accidents due to underinflated tires, the US government passed a legislation that most vehicles sold in the United States since 2007 include a tire pressure monitoring system of some kind.

Not every TPMS works the same way. The illumination of the low tire pressure indicator represents the final step in the process of either an indirect TPMS or a direct TPMS.

INDIRECT TPMS: WHAT IS INDIRECT TPMS & HOW DOES IT WORK?

An indirect TPMS typically relies on wheel speed sensors that the anti-lock brake system uses. These sensors measure the rate of revolution of each wheel and can be used by on-board computer systems to compare with each other and other vehicle operation data such as speed.

Based on the rate of revolution of each wheel, the computer interprets the size of the tires on your vehicle. If a single wheel starts spinning faster than expected based on the other tires, the computer calculates that the tire is underinflated and alerts the driver accordingly.

So, an indirect tire pressure monitoring system doesn’t truly measure tire pressure. It is not electronically processing the same kind of measurement you see with a tire gauge. Instead, an indirect tire pressure monitor simply measures how fast your tires are rotating and sends signals to the computer that will initiate the indicator light when something in the rotation seems irregular.

ADVANTAGES OF INDIRECT TPMS

- Relatively inexpensive compared to a direct TPMS

- Requires less programming/maintenance over the years than a direct TPMS

- Less overall installation maintenance than its direct counterpart

DISADVANTAGES OF INDIRECT TPMS

- May become inaccurate if you purchase a bigger or smaller tire

- May be unreliable when tires are unevenly worn

- Must be reset after properly inflating every tire

- Must be reset after routine tire rotation

DIRECT TPMS: WHAT IS DIRECT TPMS & HOW DOES IT WORK?

Direct TPMS uses pressure monitoring sensors within each tire that monitor specific pressure levelsi0.

Sensors in a direct TPMS may even provide tire temperature readings. The direct tire pressure monitoring system sends all of this data to a centralized control module where it’s analyzed, and interpreted. If tire pressure is lower than it should be, this data transmits directly to your dashboard where the indicator light illuminates. A direct tire pressure monitor usually sends all of this data wirelessly. Each sensor has a unique serial number. This is how the system not only distinguishes between itself and systems on other vehicles, but also among pressure readings for each individual tire.

Replacing a TPMS in a way that’s consistent and compatible with your vehicle will require an experienced, knowledgeable technician.

ADVANTAGES OF DIRECT TPMS

- Deliver actual tire pressure readings from inside the tire

- Not prone to inaccuracies because of tire rotations or tire replacements

- Simple resynchronization after tire rotation or tire replacements

- Batteries inside the sensors usually last for about a decade.

- May be included in a vehicle’s spare tire

DISADVANTAGES OF DIRECT TPMS

- More expensive overall than an indirect TPMS

- Though simple, resynchronization may require costly tools.

- Battery rarely serviceable; if the battery is drained, the whole sensor must be changed.

- Proprietary systems make installation, service, and replacement confusing for consumers and auto shops.

- Sensors are susceptible to damage during mounting/demounting